rockwell hardness test discussion|rockwell hardness tester least count : purchasing Indentation hardness value is obtained by measuring the depth or the area of the indentation using one of over 12 different test methods. Learn more about hardness testing basics here. The Rockwell hardness test method, as . Resultado da We would like to show you a description here but the site won’t allow us.

{plog:ftitle_list}

webVídeos porno de zoofilia con perros y caballos que follan a las chicas zoofílicas. LuxureTV es el sitio tube más grande de vídeos porno de bestialidad y sexo animal en la web. Lo .

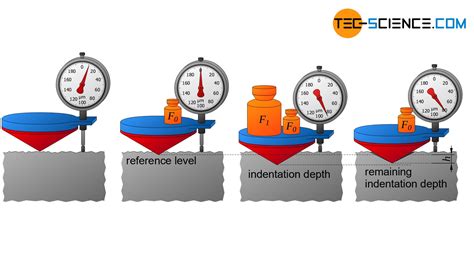

The hardness of a material by this Rockwell hardness test method is measured by the depth of Penetration of the indenter. The depth of Penetration is inversely

The Rockwell hardness test measures hardness in progressive numbers on different scales corresponding to the size of ball indentor used; scale symbols correspond to the loads of 60 .

The Rockwell hardness test is the industry standard measuring system used to determine how resistant a material is to another object. Hardness is defined as a material’s resistance to permanent indentation. This test was .Indentation hardness value is obtained by measuring the depth or the area of the indentation using one of over 12 different test methods. Learn more about hardness testing basics here. The Rockwell hardness test method, as . Hardness testing is commonly used for material evaluation due to its simplicity and low cost, relative to other assessments of these qualities. Rockwell hardness does have a relationship to tensile strength in some .Scope* 1.1 These test methods cover the determination of the Rockwell hardness and the Rockwell superficial hardness of metallic materials, including test methods for the .

rockwell hardness testing method

There are generally two methods of hardness testing, the Brinell Hardness Test and the Rockwell test. Rockwell hardness test is more favored due to its simplicity in .

The Rockwell test is based on measurement of the depth of penetration with the hardness number read directly from the dial gauge or digital display that is part of every tester. In .Created January 1, 2001, Updated February 24, 2009. The Rockwell hardness test continues to be applied as a tool for assessing the properites of a product while the tolerances on the .

The Rockwell Hardness Test is one of several tests used to determine whether a material is solid and durable enough to be employed as a component of an object. The Knoop, Brinell, and Vickers procedures are additional .The Rockwell hardness testing method fulfilled every requirement. After 100 years, it’s still the best metal strength test method. The Rockwell C scale is also the most precise way to report metal strength used in industrial machine .

rockwell hardness tester least count

Rockwell hardness test measures the permanent depth of indentation on the material by applying a fixed load using an indenter. The smaller the indentation value, the harder is the material. The Rockwell hardness test follows the .

From the comments in a subject titled "Can you tell real Rockwell Test" discussed in January 2019, it was evident that the Numismatics Society does not know what to expect, in case where a penchant with a Rockwell Test indentation, instead of being discarded, but is mixed into penchant batches, and subsequently put through the minting process, in the . The Rockwell hardness test involves making an indentation on the test material. The indenter is either a conical diamond or a steel ball. Indenter ball diameters range from 1/16 to 1/2 inches and are chosen based on the test parameters.1. Define Hardness. 2. Applications of Rockwell Hardness A ± Scale, B-Scale, C-Scale. 3. Type of Indentor used in the Three Different Scales of Rockwell Hardness Test. 4. Different Types of Hardness Testing Methods. 5. Size of the Ball to be used in Ball Indentor of Rockwell Hardness Test. 6. Di ameters of the different Balls used in Brinell . The Leeb Hardness Test, also known as the rebound hardness test, measures hardness by analyzing the rebound of an indenter, rather than the size of an indentation. It is portable and ideal for on-site testing of large and heavy components, offering a non-destructive method that causes minimal damage to finished parts and coatings.

rockwell hardness test theory

This study investigates the effects of hardening and physical factors on Al 2024 Alloy's hardness by the application of Rockwell hardness test. Its main goal is understanding the concept of hardness and examining different properties affecting hardness. . / 3 = 156.9HV Discussion Answers for questions : 1. The Vickers hardness test utilizes a .This results in 30 different Rockwell scales standardized according to ISO 6508 and ASTM E18 (e.g., A, B, C, 30N, 15T) or Rockwell test methods (e.g.: HRA, HRBW, HRC, HR30N, HR15TW), each covering different hardness ranges and consequently the widest variety of materials and applications (see table below).

The Rockwell hardness test is applied globally for the application of an experimental indentation hardness test. The Rockwell test is a quick process, very cost-effective, and non-destructive test (causing only minor indentation on the specimen material). The Rockwell hardness test is a simple process that is why it can be performed by anyone .A standardized test procedure used to determine the hardenability of steel, the Jominy test (End Quench Test) can be performed using either the Vickers or Rockwell hardness test method. When selecting which to use, you should consider relevant standards, as well as the usual criteria when choosing between different types of hardness test.

Scale C (carbide) testers are used for testing cemented carbides in the Rockwell A Scale, where tolerances of ± 0.20 of a Rockwell Hardness point are required. A specially selected “A” Brale penetrator is used to measure the hardness of cemented carbides in accordance with ASTM B 294 and the Cemented Carbide Producer’s Association (CCPA).

The Rockwell hardness test continues to be applied as a tool for assessing the properites of a product while the tolerances on the acceptable material hardness have become tighter and tighter. Adhering to good practice procedures when performing Rockwell hardness measurements and calibrations is a beneficial step to reducing measurement errors.Rockwell Hardness Testing Reference Guide ASTM E18 contains a listing of all regular Rockwell scales and typical materials for which these scales are applicable. Use these tables in selecting the scale that is appropriate for your application. Regular Rockwell Testing. In this test method, the minor (preload) is always 10 kgf. . Rockwell hardness test - Download as a PDF or view online for free. . Discussion An analog machine has it's drawbacks. Since the readings were taken manually, accuracy wasn't ensured. The weigh scale was .The Rockwell scale is one of the standard methods used to measure a material's hardness. The scale has different numbers that represent hardness based on the indent's depth caused by the test material's indentation. Let us look at how you can measure and read Rockwell's hardness value in this article.

Rockwell hardness testing process is most simple. and widely used. Therefore, we should learn it perfectly. Reference. Cliffe “Technical Metallurgy” page 150 – 154. Sergal “Material, Their Nature, Fabrication and Properties” page 143 – . View Lab - Lab report of Rockwell hardness test.docx from MTS 310 at National University of Sciences & Technology, Islamabad. Lab report of Rockwell hardness test By OBJECTIVES 1. To understand what . IT 200 Discussion Guidelines and Rubric.pdf. Shannon Huth 220249570 Written Assignment 1.docx.pdf. Answer Set 1.1 2018-13.doc. Technology and .Fast And Easy: Rockwell hardness testing is quick and easy. It does not need a microscope or microscopic observation and is suitable for batch testing. Widely Applicable: Rockwell hardness testing can test various metallic and non-metallic materials. Including steel, aluminum, copper, plastic, ceramics, etc.The Rockwell hardness test is an empirical indentation hardness test that can provide useful information about metallic materials. This information may correlate to tensile strength, wear resistance, ductility, and other physical characteristics of metallic materials, and may be useful in quality control and selection of materials. .

rockwell hardness test calculation

• Rockwell hardness testing is used to test hardness in the macro range test force within 49.03 newton (5kg) to 1471 newton (150kg). • It is a differential-depth method which used the residual depth of indentation left by the indenter is measure to determine the hardness value of a test specimen. • Indenter can be either diamond cone .3.1.2.2 Discussion—Rockwell hardness numbers are al-ways quoted with a scale symbol representing the indenter and forces used. The hardness number is followed by the symbol . 4.2 Rockwell hardness testing at a specific location on a part may not represent the physical characteristics of the whole part or end product.

These approximate relationships between hardness and tensile strength do not apply to nonferrous metals, with the possible exception of certain aluminum alloys. Related: Brinell Hardness Testing Equation. Table A Brinell Hardness to Rockwell Hardness Conversion Table

Knowing the best-suited hardness test of the three, Rockwell, Brinell, and Vickers, for your hardness test will require that you understand the determining criteria for employing any hardness test. This article aims to distinguish these methods and help you find the most suitable one for your testing situation.Rockwell hardness testing machine (b)Theory There are many de nitions for hardness depending on the material. For metals, the most appropriate one would be ‘resistance to permanent deformation’. Hardness can be calculated in many ways and using many tests. The Rockwell hardness test measures hardness by pressing an indenter into the .E 5 H – H STD (2) where: H = average of n hardness measurements H 1, H 2,.,H n made on a standardized test block as part of a performance verification, and H STD = certified average hardness value of the standardized test block. 3.2.3 The repeatability R in the performance of a Rockwell hardness machine at each hardness level, under the particular verification .

The Rockwell hardness test method is a simple process that uses a diamond cone with a round tip for harder materials and a hardened steel ball indenter for softer ones. With every test, two loads are applied to the test subject. First, an indenter is forced into the test subject under an initial load of 10kg-f, and the depth is recorded.

rockwell hardness scale examples

how to calculate rockwell hardness

Sua geladeira não está funcionando? Veja algumas possívei.

rockwell hardness test discussion|rockwell hardness tester least count